March 2018

My friend and I were flying his Cessna Citation CJ3 to Hillsboro Airport in Oregon (KHIO) from Lincoln Nebraska (KLNK) on our way to Alaska to watch the Iditarod Race . I’ve been flying this particular CJ3 for six years, in fact it was my first flight in the plane that was the impetus to obtain my CE-525S type rating . The CJ3 had just back in the air after the Rockwell Collins Pro Line Fusion avionics upgrade was completed at Duncan Aviation in Lincoln . I’ve been flying and teaching the Pro Line Fusion system since the first installation. The multiple flight legs to Alaska would provide a great opportunity to train my friend on a variety of techniques.

Before departing Lincoln I loaded the flight plans, including the second leg (Alternate Flight Plan) from KHIO to Anchorage (KPANC) using the new ARINCDirect app through the wireless connectivity of the IMS-3500 module, which was recently certified for the CJ3. I’ll write another article on that capability soon!

On Fusion you can view the Secondary, or Alternate, flight plan on the map screens of the MFD or the PFDs. This makes for a great method of verifying your next flights, or just to check the weather along the route.

Just when we were enjoying the scenery

We departed Lincoln and were cleared quickly to FL430 and were discussing different aspects of the new avionics system.

We were cruising west at FL430 flying over Idaho and we noticed the oil pressure on the right engine was lower than the left. All values had been in the green range during our flights so we had not paid a lot of attention to specific values prior to recording the values in our flight log. Our engine parameters usually match within a very close range, so it was unusual to observe a significant gap between the two engines. All other engine parameters matched as expected.

We continued our flight evaluating what may be the cause of the discrepancy. Our diagnostic steps started with any recent work on the plane. The recent Fusion upgrade and additional work we had completed should not have involved the oil system. We had previously experience a split in the oil pressure and completed a Williams International Service Bulletin for an oil check valve replacement, We thought it might be related to that replacement, however everything had been stable after that repair for some time. Each engine is equipped with two oil pressure sensors, one is a pressure switch and the other a transducer. The pressure switch is set at a particular trigger value, 23 PSI for the CJ3. The transducer measures actual oil pressure when then displays as a digital value on the avionics.

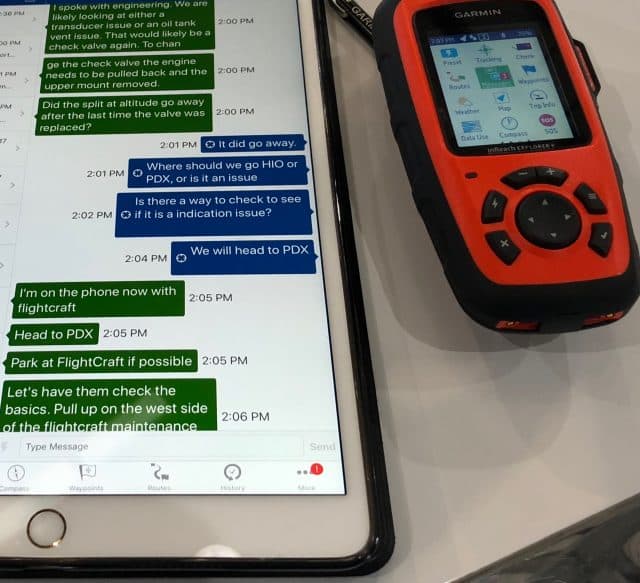

I frequently fly with my Garmin Explorer Iridium satellite communicator. It is a great device, and I have been using it, and the previous version by DeLorme, for 5 years including on my previous trip to Europe this past Fall. It allows me to send messages, track our progress, and communicate in case of an emergency. This was a great opportunity to use it again.

Near the scenic Salmon River I sent a message using the Explorer to a good friend, Troy Lewis, who works at Williams International, the manufacturer of our engines. Troy is a colleague of ours on the NBAA Cessna Citation Technical Advisory Committee and also provides customer support for Williams. The pressure had now decreased to 47 PSI, which wasn’t an immediate concern to Troy but the trend is an issue. After HIO we would be heading up the British Columbia and Alaska coastlines to Anchorage (PANC) with very few options along the way. We can fly long distances with one engine, if necessary, however it isn’t good for the engine and our range decreases on one engine since we would have to fly at a lower altitude. Neither result was good.

As we approached Oregon and our descent profile into the Portland area, the oil pressure on the right engine then started to fluctuate, something we have never seen in this plane. It would decrease a few PSI, then rise again, however the values still didn’t match the left engine. The oil pressure then started decreasing into the 40-45 PSI range, which isn’t a good sign. The minimum oil pressure in flight for the CJ3 is 45 PSI with an N2 above 80%. In typical cruise, our N2 is well above that number. Below 80% N2 the minimum is 35 PSI. The oil levels were perfect before flight, and the oil temperatures were exactly the same on both engines. Usually, but not always, you will see an increase in oil temperature if the oil pressure drops.

We were at FL430 (43,000 ft) and started to discuss our options and agreed that if the pressure decreased any more we would shut down the right engine. Troy suggested retarding the right engine and see if the pressure increase, which it didn’t. This helped us eliminate the check valve as the cause. Our issue appeared to be caused by a defective oil pressure transducer, or something worse – an actual oil leak or pump failure.

I’ve had experience a low oil pressure indication earlier in a Piper Meridian (PT6-42A) at FL270 with my wife Jane on a flight to my 40th high school reunion in Denver, and at that time thought it might be a recurring oil transducer indicating issue we had which was bothersome but not critical. We continued to happily cruise in the Flight Levels towards Denver and friends. A few minutes later I saw oil streaming over the windshield and did an emergency descent into Cortez CO. I thought it wasn’t a good idea to assume this indication was benign this time 🙂

We were landing in the Portland area and I sent Troy a message to determine Williams’ nearest support team. They stated that Flightcraft at Portland International Airport (KPDX) was a support center. Troy called their staff and texted me, not only confirmation they could help, but also which hangar door to use and who would meet us upon landing! Obviously PDX was now in our new plans. I had flown into PDX many times, when I lived in Oregon and Flightcraft had always provided excellent service. We checked the limitations sections of the AFM and both agreed if the oil pressure dropped any further and approached the limitation minimum we would shutdown the engine.

Over eastern Oregon we were now heading to PDX and the pressure started to rise a little then stabilized. We made the decision that we would shut down the engine at 34 PSI. I practice engine shutdowns both in flight and in simulators on a recurring basis. Practicing these procedures can actually be a fun and challenging experience; learning the aircraft systems and how to react to abnormal conditions. Well at least, I enjoy the challenge! A few minutes later just east of Mt. Hood, the oil pressure indication dropped to 34 PSI.

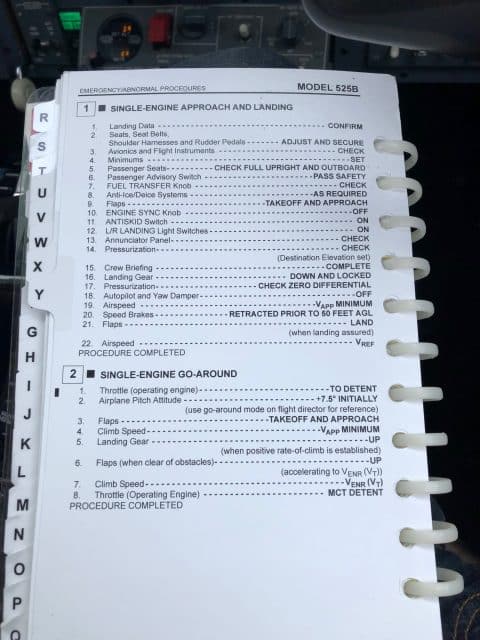

Mike was the pilot flying on this leg and went through the process of securing the engine, using the Emergency/Abnormal Checklist. It is relatively simple process, confirm the affected engine (you don’t want to shut down the good one!), pull throttle to idle, then cutoff. Secure the generator on the affected engine. You apply additional rudder trim to counteract the asymmetric power since we are now flying on one engine. The CJ3 provides ‘rudder bias’ which senses a failed engine and augments our manual rudder adjustment to help maintain coordinated flight. As we descended we monitored the respective fuel levels and used the fuel transfer system to balance our fuel. The CJ3 has a 200 pound fuel imbalance limit, with 600 possible in emergency situations.

I advised Seattle Center Air Traffic Control we had completed a precautionary engine shutdown and requested a diversion to PDX with one engine inoperative. At this point, Mike and I didn’t consider this an emergency since everything else was operating well, so an emergency wasn’t declared, only expedited handling requested. If we had felt that any significant delay would have affected our safety, or we were in immediate need of a landing, then an emergency declaration would have been appropriate for us. I have declared an emergency in other situations and it can be the best course of action and pilots should never avoid that decision that when they are in immediate need of assistance.

Descend Via but then….

As we were descending via the HHOOD4 Arrival, we were instructed to change to Portland Approach Control. We were using COM2, controlled by the second CCP (Cursor Control Panel) for that radio, while the first CCP controlled COM1 where we monitored Emergency (121.5) which was our standard. I was managing the Flight Management System (FMS) as well as communications. I switched frequencies, or at least I thought I did, and the second CCP then failed!

Now we are descending at 260-270 KIAS, 2000FPM, with a ground speed in excess of 330 KTAS. Approach Control expected us on the new frequency, which we had not activated due to the failed CCP. Our standard procedure of monitoring 121.5 on COM1 was useful, since they contacted us on that radio and we used the Quik Tune feature of Fusion to change to the appropriate frequency. Of course, you don’t expect multiple failures at the same time however it does make it more interesting.

Portland Approach was very helpful, especially when I requested no delays if possible. The plane was flying well, however it doesn’t hurt to ask for a bit of assistance. The right engine was shut down and the less time you can have an engine spinning in the wind without oil pressure, the less likely you will encounter other issues. We reviewed the Single-Engine Approach Checklist to ensure we didn’t miss any items. While we knew the plane well, the use of checklists is a good standard protocol – especially when you have an abnormal event.

We were cleared for the ILS RWY 10L by vectors to final. We were now VFR below the clouds and had a great view of the Columbia River, something I always enjoyed when we lived in Oregon.

Our approach speed was a little high on final for the ILS 10L which we adjusted on the glide path. The touchdown by Mike was perfect and we then taxied to the west side of the Flightcraft maintenance hangar that was opening – just as Troy informed us!

The Welcoming Committee was there when we landed, not only the Flightcraft team but also the Portland Airport Fire Department – just in case.

Flightcraft – Help to the Rescue

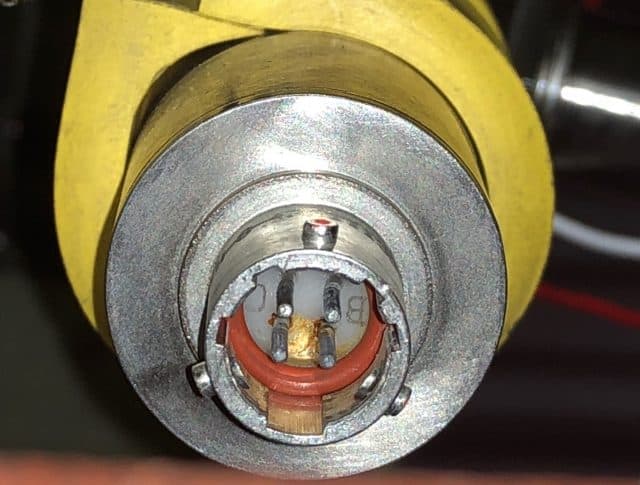

It was now approaching 1530 and our goal of reaching Anchorage that evening was no longer attainable. The technical team at Flightcraft was truly amazing. Within 30 minutes of landing, the had the cowlings off our engines, had hooked up test equipment and isolated the problem – the oil pressure transducer. The corrosion didn’t appear to be severe, however in testing we believe it extended beyond what was visible to us. They even let me help, which probably delayed them a little bit 🙂

Corrosion on Oil Transducer Pins – not the discoloration on the pins and the base of the connection.

It was now 1615. We had isolated the problem and now needed a replacement – on Friday evening no less, and then required installation. Paul, one of the supervisors at Flightcraft worked quickly and found a part at the Textron Sacramento Service Center. With everybody working hard to help us, we were able to get an airline counter-to-counter replacement on the way to PDX.

We decided to enjoy Portland, or at least the airport area, and went to dinner at Salty’s on the same river we just flew over – the Columbia. If you find yourself in Portland, it is a great restaurant with an enjoyable jazz group on Friday evenings, and you can watch planes land at PDX! We also met up with friends who needed a ride to Alaska, so it worked out for everyone.

At 10 pm the new part arrived from Textron and Scot Fitch, the A&P mechanic who stayed late to help along with a colleague, called to let me know the part had arrived. Mike and I went to the hangar to help and test run the engines. After a little additional tweaking, we had proper oil pressure! Scot and his assistant did an amazing job getting our bird back in service.

The next morning we were off to Anchorage and the Iditarod, maybe 15 hours late, but that was inconsequential and we were grateful for the excellent support by Williams, ATC, Textron, and Flightcraft! Besides it allowed us to view the spectacular British Columbia and Alaska coasts in daylight! More details on the remaining trip and the Iditarod soon…..